WINNER, WINNER! Eureka Mayor Names Artist and Business of the Year

Isabella Vanderheiden / Wednesday, July 17, 2024 @ 4:05 p.m. / Art , Business

Mayor Kim Bergel unveiled her selections for the coveted titles of Artist of the Year and Business of the Year at last night’s Eureka City Council meeting.

Out of the dozen artists and businesses selected for monthly recognition by the city’s Arts and Culture Commission and Economic Development Commission, Bergel got to hand-pick her personal favorites: multi-media artist Becky Evans and the Spa at Personal Choice in Old Town.

Many of our readers will recognize Evans as the creative mind behind “30,000 Salmon,” a collaborative art installation first assembled in 2002 to commemorate the devastating Klamath River fish kill that left more than 30,000 salmon dead. (Later counts estimated that as many as 100,000 salmon died in the ecological disaster.) The installation reemerged at Morris Graves Museum in 2023 to celebrate dam removal on the Klamath River.

“I remember when I first saw your Waterlines Project,” Bergel said, referring to Evans’ series on drought in California. “It just had this incredible impact on me [and] a sense of spiritual connection. … Thank you so much for all you do for our community and for our environment.”

Speaking at last night’s meeting, Evans thanked Bergel and the city council for the “very unexpected honor” and underscored the importance of the arts. “I really believe strongly that arts can bring people together.”

“I can see how art transforms people’s lives,” she continued. “People think, ‘Well, it’s just kind of an extra thing. It’s an add-on. It’s nice, but how does it really make a difference in people’s lives?’ I can tell you from my own experience in seeing the many, many children and students from pre-school all the way up through graduate school … their lives were impacted. … It does transform people’s lives and brings us together.”

Bergel also took a moment to highlight Susan Santsche, owner of the Spa at Personal Choice. Bergel commended Santsche, a breast cancer survivor, for having the remarkable ability to “take lemons and turn them into lemonade.”

“She spearheaded the effort to get 3-D mammography technology here in Humboldt and has undoubtedly saved many lives in our community,” Bergel said. “You’ve guided your business through the pandemic with grace. … It is truly an honor to know you and to celebrate you.”

Santsche thanked Bergel for the heartfelt acknowledgment and underscored the importance of community resilience. “I think Humboldt has something really great to offer because out of your greatest weakness comes your greatest strength,” she said. “When you don’t have everything given to you, you have to go out and create it.”

BOOKED

Today: 8 felonies, 8 misdemeanors, 0 infractions

JUDGED

Humboldt County Superior Court Calendar: Yesterday

CHP REPORTS

1465 MM101 N DN 14.70 (HM office): Trfc Collision-1141 Enrt

15400-15565 Us101 (HM office): Trfc Collision-Unkn Inj

ELSEWHERE

RHBB: ‘We Will Not Accept the Response’: Students Remain Overnight in Cal Poly Humboldt’s Nelson Hall

RHBB: Humboldt County Road Construction Notice: Central Avenue

RHBB: Electrify Home Appliances and Improve Efficiency, Says Arcata

Governor’s Office: Governor Newsom releases 2025 judicial appointment data

Humboldt County Sheriff’s Office Identifies Highway 36 Homicide Victim

LoCO Staff / Wednesday, July 17, 2024 @ 2:33 p.m. / Crime

PREVIOUSLY:

Humboldt County Sheriff’s Office press release:

On 7/14/2024 in the late evening, Humboldt County Sheriff’s deputies were dispatched to the 27000 block of Highway 36 near Bridgeville to investigate the report of a possible shooting. Deputies responded and located one deceased male. Melvin Portillo, age 20 of Sacramento, California, was subsequently arrested for homicide. There are no outstanding suspects or parties, and there is no danger or threat to the public.

Next of kin has been notified. The identity of the decedent has been positively identified as Rafael Orlando Castillo-Cortes, age 34, of Sacramento. Castillo-Cortes and Portillo were known to each other prior to this incident. An autopsy is scheduled for later this week to determine the cause of death.

The Humboldt County Sheriff’s Office extends our deepest sympathies to Rafael Orlando Castillo-Cortes’s family and friends during this difficult time. Anyone with information about this case or related criminal activity is encouraged to call the Humboldt County Sheriff’s Office at (707) 445-7251 or the Sheriff’s Office Crime Tip line at (707) 268-2539.

Humboldt County Sheriff’s Office Provide Details on Latest Sex Offender Registration Compliance Check

LoCO Staff / Wednesday, July 17, 2024 @ 1:52 p.m. / Crime

Press release from the Humboldt County Sheriff’s Office:

Periodically between the end of May and the end of June, Humboldt County Sheriff’s Office investigators conducted a sex offender registration compliance sweep throughout the County of Humboldt.

During this sweep, law enforcement attempted to contact approximately 168 registered sex offenders to ensure each offender was in compliance with state requirements. Pursuant to California Penal Code 290, sex offender registrants are required to register in person with the law enforcement agency that has jurisdiction where they reside. The registrants must also comply with several registration requirements, such as updating their registration annually and informing law enforcement when any changes have been made to their address or registration information. Failure by a sex registrant to keep law enforcement notified of an address change or registration information is a crime and can be punished as a felony or misdemeanor.

During the compliance sweep, no registrants were found to be out of compliance. One was determined to be deceased, one is currently in federal custody, and one is confirmed to be living out of state. Thirteen registrants were unable to be contacted. Continued efforts will be made to contact and determine compliance of the outstanding registrants.

This month’s operation is part of an ongoing effort to do smaller, more frequent 290 sweeps to reduce violent sexual offenses in the county through proactive surveillance and arrest of habitual sexual offenders, and strict enforcement of state registration requirements. The Humboldt County Sheriff’s Office involvement in this enforcement effort is funded through the Sexual Assault Felony Enforcement (SAFE) grant.

The Humboldt County Sheriff's Office would like to thank participating agencies for their assistance in this operation.

State Senator Mike McGuire Issues Statement Denouncing Political Violence in Response to Trump Assassination Attempt

LoCO Staff / Wednesday, July 17, 2024 @ 12:43 p.m. / Politics

From the office of Mike McGuire:

Senate President pro Tempore Mike McGuire (D-North Coast) and Senate Minority Leader Brian W. Jones (R-San Diego) issued the following statement regarding concerns over safety and political unrest following the assassination attempt at a Trump rally in Pennsylvania:

“The political violence we saw in Pennsylvania over the weekend was horrific — an innocent person was killed, people were injured, and the nation’s former president came close to being assassinated. This event, and so many other acts of political violence over the past few years, must serve as a wake-up call. We need to stand united and condemn all political violence.

“We are more determined than ever to not let violent attacks and dangerous rhetoric win the day here in the Golden State. As we get ready to embark on the final weeks of this Legislative session and the election ahead, we are reaffirming our commitment to protect democracy. Together, we are going to ensure the safety and security of the people of California, all those who come to the Capitol to exercise their First Amendment rights, our colleagues and our hard-working staff.”

Hill Fire Grows to 3,437 Acres as Crews Attempt to Overcome Dry Weather and Steep Terrain

LoCO Staff / Wednesday, July 17, 2024 @ 11:14 a.m. / Fire

Reader submitted photos of smoke rising from the Hill Fire near Willow Creek on Tuesday

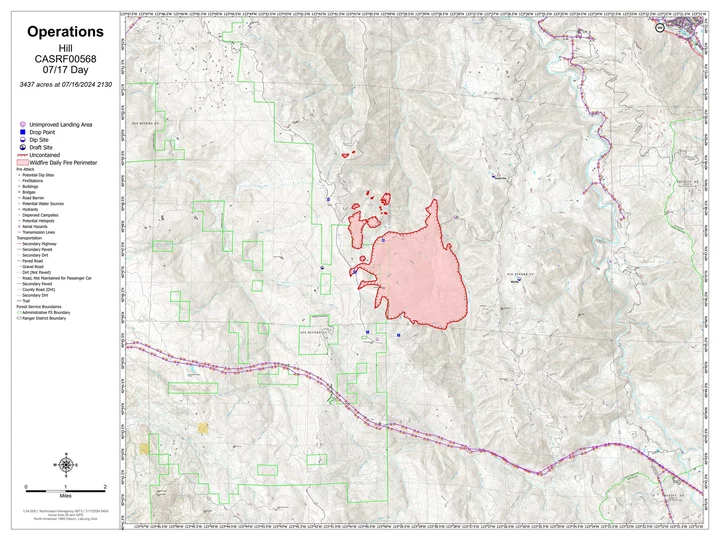

As of Wednesday morning, the Hill Fire burning south of Willow Creek is now listed at 3,437 acres with 0% containment. The blaze continues to be difficult for crews to access from the ground due to the steepness of the terrain where it is burning. Numerous air attack resources are on hand to help manage expansion.

“Due to dry and hot weather conditions today fire activity is expected to be high with the potential for a rapid rate of spread and extreme fire behavior,” said a release from Six Rivers National Forest.

Below is the latest released map showing the wildfire’s perimeter.

Click to enlarge

The following additional information comes from Six Rivers National Forest:

The Hill Fire is now being managed in Unified Command between the U.S. Forest Service and CAL FIRE. In addition, a local Type 3 Incident Management Team arrived today to assist with managing the fire and a Complex Incident Management Team and a CAL FIRE Incident Management Team has been ordered.

The fire is burning in steep and remote terrain making access challenging for ground resources within the Buck Creek and Mosquito Creek Drainages. Federal and state air resources including air tankers, helicopters, and air attack are on scene and will continue to perform retardant drops to try and slow the spread today. The fire is growing to the north in heavy timber.

Due to dry and hot weather conditions today fire activity is expected to be high with the potential for a rapid rate of spread and extreme fire behavior.

Crews will begin to provide structure protection along Route 1 and within the Friday Ridge communities. At this time there are multiple structures threatened. Firefighters are working to construct direct and indirect line to control fire spread to the north and the west.

Additional ground resources continue to be ordered and arrive on scene.

Evacuation Information:

Evacuation order and warning remain in effect. For current updates on evacuations, visit https://www.facebook.com/HumboldtSheriff and https://humboldtgov.org/2383/Current_Emergencies. Conditions are subject to change at any time, visit

https://protect.genasys.com/search for a full zone description.Sign up for Humboldt Alert emergency notifications at

https://humboldtgov.org/2014/Emergency-NotificationsEvacuation Order Issued for Zone HUM-E077-A: Due to the Hill Fire, the Humboldt County Sheriff’s Office has issued an immediate evacuation order for zone HUM-E077-A North of White Oak Creek/Grouse Creek, South of Friday Ridge Road, Forest Route 6N08A, East of Titlow Hill Rd, Twin Lakes Creek, West of Mosquito Creek/Madden Creek. Those in this zone should leave now for their safety.

Evacuation Warning Issued for Zone HUM-E077-B: Due to the Hill Fire, the Humboldt County Sheriff’s Office has issued an evacuation warning for zone HUM-E077-B North of PG&E Rod, Grouse Creek, South of Madden Creek, Forest Route 6N06, East of Mosquito Creek/Madden Creek, West of Trinity County Line. Prepare for potential evacuations, including personal supplies and overnight accommodations. Those in this zone should prepare to leave at a moment’s notice. More information will follow if an evacuation order is issued.

Closures:

Road closure is in place at Friday Ridge Road at Forest Service Route 6N06.

Fire Restrictions:

Forest fire restrictions currently in effect across the Six Rivers National Forest. Campfires and stove fires are restricted to those developed areas listed in the forest order located at https://www.fs.usda.gov/Internet/FSE_DOCUMENTS/fseprd1188610.pdf.

Smoking, welding, and operating an internal combustion engine also have restrictions in place.

Additional Fire Information:

The Hennessey 2, Ridge 2, and Waterman Fires are all staying within their fire perimeters of less than a quarter acre each. This will be the last update for the Hennessey 2, Ridge 2, and Waterman Fires unless significant activity resumes.

California Passed a Law to Fix Unsafe Homeless Shelters. Cities and Counties Are Ignoring It

Lauren Hepler / Wednesday, July 17, 2024 @ 7:05 a.m. / Sacramento

The O Lot Safe Sleeping site at Balboa Park in San Diego on March 22, 2024. Photo by Kristian Carreon for CalMatters

Now that the Supreme Court has granted cities more power to ban sleeping outside, homeless Californians face a crucial decision: Try to get into a shelter, or risk going to jail.

Those able to find a shelter bed will step into a world rife with reports of violence, theft, health hazards — and a lack of accountability. Public records obtained by CalMatters show that most cities and counties have seemingly ignored a recent state law that aimed to reform dangerous conditions in shelters.

In 2021, following earlier reports of maggots, flooding and sexual harassment in shelters, the state Legislature created a new system requiring local governments to inspect the facilities after complaints and file annual reports on shelter conditions, including plans to fix safety and building code violations.

CalMatters found that just 5 of California’s 58 counties — Lake, Los Angeles, Monterey, Orange and Yuba — have filed shelter reports. Only 4 of the state’s 478 cities filed reports: Fairfield, Petaluma, Santa Rosa and Woodland, according to records from the agency in charge of implementing the law, the California Department of Housing and Community Development.

“It is shocking, number one, that there is so little reporting, considering that is part of the legislation,” said the law’s author, Assemblymember Sharon Quirk-Silva, a Democrat who represents parts of Orange and L.A. counties. “We are asking for the basics here.”

In light of CalMatters’ findings, she said she has requested a meeting with officials at the state housing agency. Quirk-Silva said she will consider audits or other measures as needed.

“Maybe we need to add more teeth,” she said. “There certainly could be a possibility that we will follow up with another piece of legislation.”

Police call logs, shelter incident reports and other records obtained by CalMatters provide a hint of what’s missing as a result of the failure to report: a child falling out of an unreinforced window in San Mateo County and being hospitalized; multiple allegations of sexual harassment in Contra Costa County; food shortages in Placer County; and deaths, mold and vermin in many places across the state.

California has spent at least $1.5 billion on shelters and related solutions since 2018, legislative reports show, on top of millions invested by cities, counties and the federal government. The facilities are designed to be a temporary stop on the road to regaining housing but increasingly function as a bridge to nowhere; the state added new emergency shelter beds at roughly five times the rate of permanent housing with supportive services from 2018 to 2023, gaining 27,544 shelter beds, federal data shows.

What happens in those shelters is largely a black box. No state agency keeps an updated list of how many shelters are operating, or where, officials told CalMatters. There is no state licensing process for shelters. The U.S. Department of Housing and Urban Development tracks numbers of emergency shelter beds and how long people live in them, but no information about resident deaths, health or safety.

First: A former homeless shelter in Anaheim that has been permanently shut down and boarded up. Last: An area where folks experiencing homelessness were given space to store their belongings while staying at the shelter that has since been permanently shut down in Anaheim, on May 14, 2024. Photos by Jules Hotz for CalMatters

First: A former homeless shelter in Anaheim that has been permanently shut down and boarded up. Last: An area where folks experiencing homelessness were given space to store their belongings while staying at the shelter that has since been permanently shut down in Anaheim, on May 14, 2024. Photos by Jules Hotz for CalMatters

While not every city or county in California has a homeless shelter, state housing officials estimated a total of around 1,300 shelters in 2021. Municipalities continue to invest in them as a more immediate alternative to street homelessness, even as experts stress that other options – such as direct rent subsidies or housing with on-site services – are often more effective at combating the root issue.

“It’s a bad idea. At the same time, so many unhoused people are living in these congregate shelters,” said Eve Garrow, a senior policy analyst and advocate for the ACLU of Southern California. “We want to make sure those spaces are safe and clean for as long as people need them, but we also want to move away from that model.”

The 2021 state law was supposed to help enforce minimum building and safety standards for shelters by creating a new state oversight system. When people staying at shelters or their advocates file complaints, the law requires cities or counties to inspect the facilities and report any violations to the state to reconsider future funding. The catch: cities and counties only have to report to the state if they determine that a violation is severe enough.

“Each city and county has a very unique way of processing complaints,” said Mitchel Baker, assistant deputy director of the Department of Housing and Community Development’s codes and standards division. “What may be perceived as complaints or violations may not ultimately result in the issuance of a notice of violation or corrective order.”

As California and the rest of the country barrel into a new legal era for mass homelessness, promises of safe shelter will be key to determining how many people can avoid more frequent tickets or jail. Many public officials, meanwhile, cast the Supreme Court’s Grants Pass ruling as a necessary clarification after years of conflict over when cities should be allowed to dismantle tents, insisting that they will continue to offer alternatives.

“This decision removes the legal ambiguities that have tied the hands of local officials for years,” Gov. Gavin Newsom said in a statement after the ruling. “The state will continue to work with compassion to provide individuals experiencing homelessness with the resources they need.”

What those resources are is often hard to know, since many shelters are closed to visitors and so few places have filed state reports on conditions. People who have lived in shelters, however, paint a more dire picture.

Residents of one Huntington Beach shelter recently complained to health officials about mold, never-ending cases of pneumonia and neighbors walking around with infected, open sores. Homeless people and their families have filed lawsuits in several cities over shelter sexual assaults and wrongful deaths. In San Diego, Sharon Descans has been bouncing between shelters and a borrowed van after being evicted from a newer kind of publicly-funded tent city, where she said she weathered unpaid labor, multiple neighbors’ deaths and flashes of chaos.

“People are pulling swords on each other and hitting each other with two-by-fours,” Descans said. “All I wanted from the day I got there is to get out.”

Sharon Descans at the Chula Vista Bayfront Park on June 23, 2024. Descans has been staying in shelters and a van after getting evicted from the O Lot Safe Sleeping site in San Diego’s Balboa Park. Photo by Kristian Carreon for CalMatters

Sharon Descans at the Chula Vista Bayfront Park on June 23, 2024. Descans has been staying in shelters and a van after getting evicted from the O Lot Safe Sleeping site in San Diego’s Balboa Park. Photo by Kristian Carreon for CalMatters

Old problems, new failures

Up until the 1980s, many of the poorest people in California and other states could still afford rented rooms or cheap hotels. Then came a tidal wave of gentrification, wage stagnation, federal cuts to housing and cash aid, plus shocks like the AIDS and drug epidemics. In less than three decades, the state went from 37,000 dedicated beds for mental health patients to just 2,500 by 1983, according to historians at the National Academies of Sciences.

Vast numbers of people “drifted onto the streets,” the historians wrote, as promised investments in community resources proved inadequate. The “modern era of homelessness” had begun.

Large emergency shelters with bunk beds and communal showers emerged as a stop-gap, despite comparisons to jail cells or military barracks. The shelter triage approach spread as California housing construction slowed and homelessness exploded, up 40% in the past five years alone, to more than 181,000 people.

Shelters boomed thanks in large part to court rulings that forbid authorities from cracking down on homeless people solely for being homeless. In Martin v Boise, courts decided that the city violated the U.S. Constitution’s ban on cruel and unusual punishment by ticketing people for sleeping outside when there wasn’t “adequate” shelter available.

“What has happened is cities and counties have quite explicitly raced to build more shelters in order to criminalize more people,” Garrow said. “Shelters become kind of an arm of this criminal legal system.”

Quirk-Silva proposed the 2021 shelter law after a 2019 ACLU report by Garrow documented bedbug infestations, overflowing sewage and sexual harassment by shelter workers. The findings collided with Quirk-Silva’s experience talking with people on the street near her Fullerton neighborhood about why they weren’t in shelters. Her own brother died at age 50 after struggling with housing instability, mental health and alcohol abuse.

Shelters were growing, fast, Quirk-Silva realized, and people were staying longer. California shelter residents now stay a median of about five months, or 155 days, the most recent federal data from 2023 shows — a 30% increase since 2019.

Garrow supported the 2021 law’s effort to create minimum standards for shelters. She has seen a few problematic shelters closed down in Orange County, she said, including an old transit station in Santa Ana not meant for human habitation, which previously flooded.

Still, Garrow wasn’t surprised to hear about the small number of cities and counties following through on the law, which she said several amendments weakened. One removed a requirement for local officials to regularly conduct unannounced shelter inspections. Another struck a rule to add signs with information about how to file complaints at shelters.

“I would attribute the low number of complaints not to the fact that shelters are now clean and sanitary and abiding by a new law,” Garrow said. “But to the fact that people aren’t aware.”

Under the law, cities and counties that find violations in their shelters are supposed to report any conditions that are “dangerous, hazardous, imminently detrimental to life or health, or otherwise render the homeless shelter unfit for human habitation.” But even places that are filing state shelter reports omit serious potential safety issues.

L.A. County, for example, has filed lists of its several dozen shelters and one-page inventories of violations related to rats, roaches, hot water outages and garbage. Not mentioned were issues like a 2021 conviction of a former shelter security guard on multiple sexual assault charges. Or reports of shelter deaths, physical attacks and other incidents that appear in police call logs requested by CalMatters.

Shelters after SCOTUS

On a recent Friday in San Diego’s crown jewel of a central park, Balboa Park, Sharon Descans laid down on a concrete bench under a palm tree to ease the pain in her joints after a year of constant motion. The former college swimmer said she became homeless for the first time last year, after she got sick with COVID, lost two property management jobs, fell behind on rent and got evicted.

What followed was a tour she never wanted of last-ditch housing in a city at the forefront of statewide efforts to vanquish street encampments.

Even before the Supreme Court decision, San Diego officials were moving people off the street to large publicly funded tent cities, called “safe sleeping” sites.

At a site called O Lot, Descans and many neighbors lived in Eskimo brand ice fishing huts that multiple residents said were prone to leaking during rain. Her anxiety spiked at the makeshift shelter, she said, since she didn’t have a door to lock and witnessed widespread drug use and unpredictable outbursts. One neighbor died of cancer alone in his tent, Descans said, after what seemed like days without anyone checking on him.

A San Diego Police Department patrol vehicle drives past an encampment in downtown San Diego on March 22, 2024. Photo by Kristian Carreon for CalMatters

A San Diego Police Department patrol vehicle drives past an encampment in downtown San Diego on March 22, 2024. Photo by Kristian Carreon for CalMatters

First: O Lot Safe Sleeping site tents at Balboa Park in San Diego on March 22, 2024. Last: Inside a tent at the O Lot Safe Sleeping site at Balboa Park in San Diego on March 22, 2024. People are given a cot, blanket, sleeping bag, and hygiene kit. The site also offers 24/7 staffing, showers, laundry, and shuttles. Photos by Kristian Carreon for CalMatters

First: O Lot Safe Sleeping site tents at Balboa Park in San Diego on March 22, 2024. Last: Inside a tent at the O Lot Safe Sleeping site at Balboa Park in San Diego on March 22, 2024. People are given a cot, blanket, sleeping bag, and hygiene kit. The site also offers 24/7 staffing, showers, laundry, and shuttles. Photos by Kristian Carreon for CalMatters

None of that has been captured in state reports. San Diego is one of the many California locales that has not submitted any reports after the 2021 shelter law, according to state records, despite housing more than a dozen shelters and some 10,600 homeless residents.

(Even if San Diego had filed the reports, state and local spokespeople said it’s not certain they would’ve captured operations at O Lot. Though many homeless people have temporarily lived at the tent site, nonprofit operator Dreams For Change stressed that it is not technically a shelter under federal definitions.)

When asked whether there was any process in place for complaints about homeless shelters in San Diego county, a spokesperson said only that the county does not directly operate any shelters. Under the state law, cities and counties are still responsible for monitoring complaints and reporting violations at shelters in their area with other owners or operators.

A spokesman for the city of San Diego said that it has received five complaints since the shelter law was passed, and that “city staff are working on” evaluating why a state report had not been filed.

“At all city-funded shelters, including the Safe Sleeping and Safe Parking programs, there is a comprehensive complaint process where potential issues are quickly and thoroughly resolved,” spokesman Matt Hoffman said in a statement. “Every complaint is followed up on and, if needed, action is promptly taken.”

At O Lot, Descans tried to keep her head down. She made friends with another mom whose son had also wrestled at a nearby high school. The pair heard they could earn money to work their way out of the tents by cleaning bathrooms and doing laundry for the nonprofit Dreams for Change. Descans said she was never paid around $1,000 for 55 hours of cleaning work, which she documented in photos and text message complaints to a site supervisor.

In June, Descans was “exited” from the shelter — nonprofit-speak for evicted — after forms said she had a verbal altercation with staff and allowed an unpermitted visit from her 17-year-old son, who lives with other family.

“I just feel like nobody cares,” Descans said. “It’s like cover your ass at any expense — who even cares about these homeless people?”

A Dreams for Change spokesperson said the nonprofit cannot comment on individual cases, but that it has a process for formally hiring and paying residents who wish to work. The nonprofit added that it is one of several contractors that operate safe sleeping sites near Balboa Park.

About 80 households have secured permanent housing after living at Dreams for Change’s portion of O Lot, spokesperson Kelly Spoon said in a statement. She confirmed three deaths at the site and added that, “Dealing with a diverse population, occasional altercations may arise, but physical altercations are extremely rare.”

Another current resident of the safe sleeping site, who asked not to be identified due to fear of retaliation, said he was also concerned about a lack of sufficient meals, deaths, sexual assaults reported by female neighbors, and a nagging lack of information from caseworkers about housing options.

“The animals almost get better treatment than the people,” he said. “You keep shitting on people, you’re going to get shit results.”

Shawn Swearigen also lived in a tent at O Lot before moving to a subsidized apartment last month. The grandson of a cattle rancher from Imperial County worked in construction for years, until family deaths and the 2008 housing crash landed him on the street.

Shawn Swearingen, 55, at the O Lot Safe Sleeping site at Balboa Park in San Diego on March 22, 2024. Photo by Kristian Carreon for CalMatters

Shawn Swearingen, 55, at the O Lot Safe Sleeping site at Balboa Park in San Diego on March 22, 2024. Photo by Kristian Carreon for CalMatters

The tent in Balboa Park “wasn’t bad,” he said, though it wasn’t immune from theft and mental health crises that he has found are two constants of homelessness. Swearigen valued having his own space, as opposed to being “dormed up” in a bunk bed like when he first became homeless and stayed at a large shelter. It was so claustrophobic and counter-productive, he said, that he spent the next decade trying to stay out of sight, often camping in the woods.

“It was kind of like a lack of options,” Swearigen said. “I really didn’t want to be a burden on people.”

Have you stayed at a California homeless shelter? Tell us about your experience here.

###

CalMatters.org is a nonprofit, nonpartisan media venture explaining California policies and politics.

OBITUARY: Jeannie Diana Gray, 1947-2024

LoCO Staff / Wednesday, July 17, 2024 @ 7 a.m. / Obits

It is with great sadness that we announce the passing of our mother and grandmother. Born in Southern California, Jeannie had a busy childhood surfing Venice Beach and diving for coins thrown by visitors from the steamer ships at Catalina Island with her 6 siblings. She also recalled visiting Disneyland with her family when she was 8 on just the third day the park was open. At 4 foot 11, Jeannie was a feisty woman full of zest. She loved growing up near the ocean and enjoyed the summers at her family’s cottage in Catalina. She was tenacious like her mother with a great commitment to excellence.

She met our father, Kenneth Gray, in 1967, following the birth of her first daughter, marrying in 1968. One of her greatest regrets was not being able to raise her first child, Kylie Hansen, who found her and our family 29 years later. From then on, Kylie was one of us like we never missed a beat. Jeannie was so happy to have her 3 daughters together for the weddings of her other two daughters, Colleen and Ginger. She and her husband Ken moved from Southern California to Fortuna in the summer of 1977 with their two daughters. They knew no one in the county. The economy was challenging, and it took some time to find work. Jeannie ultimately went to work for Jacque Debets Realty, then Crown Redwood and then finally Pacific Lumber Company, for which she was most proud of. It was not an easy job for her to get and working in the factory with her short stature was challenging. She was a very hard worker and most of all she was motivated to afford a lifestyle that would help to care for her family. Jeannie retired early and had a second calling, caring daily on weekdays for her nearby grandchildren, Kira and Hayden, until they were old enough to stay home alone. She and Ken loved their outings with the grankids, taking them to restaurants and activities and teaching them about various cultures. Those were some of the happiest years of her life. She also enjoyed their trips in their motor home with their Siamese cat, Bluesy. Jeannie was also a talented stained-glass artist and crafter. She enjoyed writing and had a natural way with words. She loved her home, gardening and most of all, cooking for her family. She was also quite funny and a natural problem solver. Her ability to get to know strangers quickly and make a connection was admirable.

Our mother’s health faltered in recent years but her tenacious spirit continued. She worked to get the most out of her days, exercising and advocating for herself and others. This past year, her daughter, Ginger, took her to lunch every Saturday where she enjoyed fish and chips whenever possible.

Her greatest loves were her three daughters, Kylie, Colleen and Ginger and her four grandchildren, Emmeline, Kira, Olivia and Hayden. She was always so proud of how well they were doing and the careers they had developed. She was most proud that all 3 of her children were college graduates. Something that was not an option for her. She was also proud that her grandchildren were completing their education and that they were all hard workers. She will continue to be their ongoing champion, watching from above, cheering them on to have their best lives. She would want nothing but the absolute best life for each of them. That is for certain. Her greatest act of selflessness was giving up her first child for adoption and that was the epitome of our mother. She worked hard to provide for her family. She was the exact opposite of selfish. She was loving and caring, often to the sacrifice of herself. A mother’s love like none other. That was our mother, our grandmother. We love you and miss you already.

Jeannie is survived by her three daughters, Kylie Hansen (Kris), Colleen Dunaway (Paul), Ginger Weber (Mike) and her four grandchildren, Emmeline Dunaway, Olivia Dunaway, Kira Weber and Hayden Weber. She was predeceased by her husband, Kenneth Gray, and three of her siblings. We thank her primary care provider, Dr. Lei Han, for her compassionate and diligent care, and for helping our mom and our family to navigate her health concerns this past year.

Jeannie will be laid to rest in Fortuna with a small gathering with her family. We hope you cook a nice meal for your family or complement them for a job well done in honor of our mother. She truly was one of a kind!

###

The obituary above was submitted on behalf of Jeannie’s loved ones. The Lost Coast Outpost runs obituaries of Humboldt County residents at no charge. See guidelines here.