The manufacturing of bricks was an established industry in Humboldt County from the year 1855, as a growing need for them developed to supply the construction trade.

It was expensive to order the heavy product shipped to the North Coast, so local means of production was sought. It was found that clay of good quality was in abundance throughout Humboldt County.

The brick made in Humboldt County was the common red brick. It was used in the building of walls, fireplaces and chimneys. The principal material used in the making of brick is the clay. It contains sand and small quantities of iron, magnesia, lime, potash and other minerals. Each of these substances has an effect upon the color, hardness and durability of the finished brick.

In the early days, Humboldt bricks were made by hand; the clay was mixed with water in a pug mill, sometimes with a horse and a turnstile to operate it. The clay was then placed in molds, pressed and removed from the molds and laid in the sun to dry or placed under cover for a few days. They were then stacked in a kiln and fired.

As soon as machinery could be brought into Humboldt County nearly all bricks were made much easier and much faster using the stiff mud process. In this process, the clay was thoroughly ground and water added to make a stiff mud. After the mud was mixed in a pug mill, it was placed in a machine having a die or opening the exact size of the brick.

This machine, with a large screw, forced a continuous bar of clay through the die. As it emerged it was cut into bricks by a series of steel wires like a cheese cutter, slicing about 12 bricks at a time.

The soft bricks were placed on a pallet holding about 84 bricks each; they were then put in a drying shed with open sides and dried for a considerable length of time, sometimes for thirty days. Next, they were moved and stacked in the kiln, which is like a large oven. The bricks were spaced to allow the heat to circulate around them. These kilns held from 60,000 bricks, or more, at one time, depending on the size of the kiln. A slow heat was applied using wood for about three or four days. Then the oil burners were turned on. About 12 burners, spaced around the bottom of the kiln, brought the temperature to 1900 degrees and it was held at that level for three days, or when the operator determined the firing was complete. The burners were shut off and the kiln allowed to cool slowly.

When the bricks cooled they were removed from the kiln and graded according to color, hardness, straightness and quality and stacked on pallets. The bricks that were too close to the burners were called clinkers and deemed not suitable for most work. The bulk of the bricks were ideal but some, too far from the heat, tended to he a little softer. It was not until 1891 that brickyards introduced facilities for making drain tile. The drain tiles were made in much the same manner except for a different die. The clay used was the same. The tiles were made in various sizes from three-inch in diameter to 10 inches, and were all 12 inches in length.

There are other kinds of brick which had to be shipped into Humboldt such as face brick, pressed brick, fire brick, glazed brick, paving brick and hollow brick, to name a few.

The size of most common brick is 2 1/4 inches thick, 3 3/4 inches wide, and 8 inches long; this size varies in different locations. The weight of a common brick is about 4 1/2 pounds. During the period of time from 1870 to 1930, the local bricks were used in many buildings, such as the Carson building which housed the Ingomar Theater, the Eagles building on Fifth Street, the Carnegie Library, the old county jail and many other buildings in lower downtown which are still standing. Brick was used for foundations in many of the old Victorian homes.

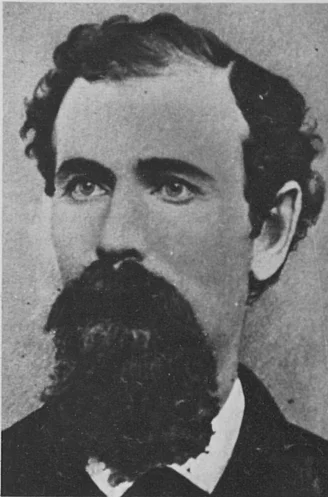

In the years 1880 to 1900, there were six major producing brickyards in Humboldt County. In 1891 the first tile machine came to the area for a brickyard near Rohnerville, west of the railroad. This yard was owned by James D. Thompson, who later sold out and moved his operations. He purchased the brickyard on the Eureka Slough, at the north end of John Hill Road, from John E. Hill who started the yard. Hill was the father of Arthur W. Hill, former district attorney for Humboldt County, and grandfather of Arthur W. Hill, attorney.

Sometime during the early 1900s, James D. Thompson leased the brickyard to John A. Porter, and he changed the name to Eureka Brick and Tile Co. During this time Porter had a man working for him at the brickyard called, “Andy Bear.” The reason for the name? He had a pet bear chained at the brickyard. Later James Thompson again took over the operation.

In 1890, John B. Hill, a cousin of the former Hill, purchased ten acres at 1900 Harrison Avenue, just north of the county hospital, and built a brickyard which he operated for two years with his brother, William. He operated it by himself for twelve more years. In 1904, he closed the brickyard and started raising strawberries on the land. He had built a fine home at 1904 Harrison Avenue. Here, he raised seven children, among them a daughter, Edith, who married Peter McRae, a grocer. A son, Wesley, was at the Eureka Post Office for years, and a son. Warren, was with the Western States Gas and Electric Co. when he was accidentally electrocuted. Another son, Chester, was a shingle weaver in Eureka.

Getting back to brickyards, there was one in Arcata, one in Fields Landing and one just south of Harris Street between Williams and D streets in Eureka. This yard was owned and operated by Jesse N. Lentell, a civil engineer. He served as Eureka city engineer for eleven years and lived near the brickyard at 3120 D Street. The brickyard operated from 1887 to 1915. Elzie Daily located a brickyard in Arcata, on property north of 14th Street and between L and M streets. Block No. 292. This yard furnished bricks for many Arcata buildings including the John Hill built this home at 1904 Harrison Ave. The brickyard was Jacoby Building. The building, now owned by Brizard’s, stands just south of the plaza. (This information was published in the Arcata Union in 1956, and was given to me by Mrs. Martha Roscoe.)

James D. Thompson operated his brick and tile yard on the Eureka Slough, employing about ten men most of the time, and turned out many thousands of bricks and tile until the 1930s. After this period, lots of other material came on the market and the railroad and trucks hauled bricks in from the south. This was the last brickyard left in Humboldt County.

In 1946, Thompson met a young man and sold him the brickyard, staying with him for a few months to teach him the trade. This young man was Henry Hindley. Hindley and his wife, Lorene, continued to operate the business until 1956. After the earthquake of 1954, which damaged m.any chimneys, there was a demand for a good many common bricks. Together, they fired the last kilns of bricks to be fired in Humboldt County, turning out over 120,000, which they quickly sold. Their brick machinery was very old and obsolete and there was too much outside competition. So, they decided to close shop and tear down the plant. They still live on the original site in their nice brick home built from their own bricks.

During the year 1884, when it was decided to build a new Humboldt County courthouse, a brick mason by the name of John Depew, who lived at 1217 Bay Street, could see that many bricks would be needed in this construction. So, he located some suitable clay for brick. The site was at the south end of the present-day Cooper Gulch near 14th Street. Here he built a brickyard and kiln, dug a well for water and turned out many thousands of bricks used in the construction of the new courthouse.

The first bricks were laid there on May 29, 1885, and the cornerstone was laid by members of Humboldt Lodge #79 F. & A.M. on July 4, 1885, along with a very large celebration. In 1954, an earthquake damaged the old courthouse beyond repair, and after seventy years of service it was demolished. Many thousands of the bricks were cleaned and salvaged and have since been used for building faces, fireplaces and other projects in the Eureka area. Thousands of these old bricks were not usable so were hauled and dumped as fill in the same location where they were made in the gulch near 14th Street.

Some idea of the size of the brick industry in Humboldt County is shown in production figures for the years 1890-1893. During this period, the brickyards employed 42 men and produced approximately 4,480,000 bricks and 17,000 yards of drain tile. This material was sold for use in the county.

CLICK TO MANAGE