Simulation of the proposed Nordic Aquafarms facilities on the Samoa Peninsula. | File image via County of Humboldt.

###

Three months after cutting bait on plans to build a $500 million fish factory in Belfast, Maine, Nordic Aquafarms is courting new investors and facing a longer, more complicated timeline for a similar project along Humboldt Bay.

In a recent interview, Nordic executives outlined some new permitting and environmental mitigation hurdles and said it will likely be “a few years” before the company can demolish the old pulp mill infrastructure on the Samoa Peninsula and break ground on its proposed recirculating aquaculture system (RAS) facility.

Announced more than six years ago, the land-based fish farm, as originally conceived, is expected to cost $650 million and employ up to 150 full-time workers while producing up to 27,000 metric tons of Yellowtail kingfish per year — enough to supply West Coast markets from Seattle to Los Angeles and beyond.

However, given the recent geopolitical upheaval and its impact on world financial markets, the future of any project with such a long timeline is uncertain, as the company saw in Maine. Nordic’s East Coast project, announced in 2018, received all required local, state and federal permits but faced fierce opposition from environmental groups, whose legal challenges ultimately proved too costly.

“The company exits after tens of millions of investment dollars and many years of planning and permitting in the State of Maine,” CEO Brenda Chandler said in a January press release.

Last week, Chandler and local Project Manager Scott Thompson sat down for an interview at Outpost headquarters in Old Town Eureka. They said that while the project is progressing, certain steps may take longer than anticipated.

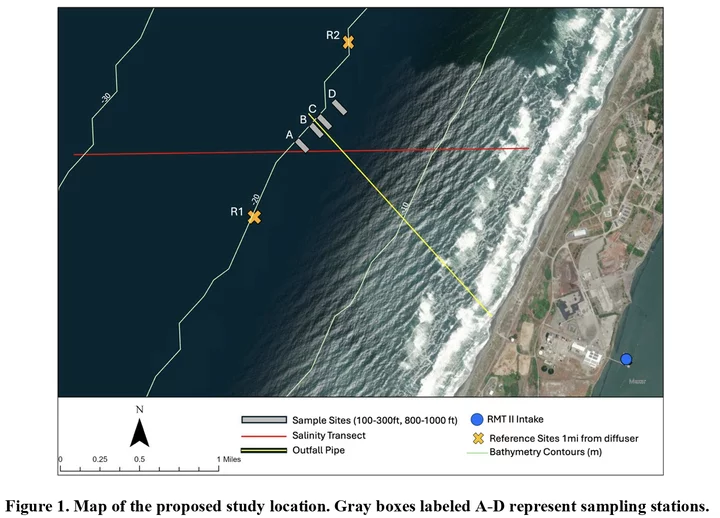

Environmental mitigation, for example. Nordic recently committed to an extensive Marine Monitoring Survey Plan that requires up to five years of water quality sampling and marine ecosystem analysis near the business end of an outfall pipe, which will discharge treated effluent from the RAS facility into the ocean, roughly a mile and a half offshore. That monitoring plan recently received approved from the North Coast Regional Water Quality Control Board.

Meanwhile, after years of analysis and deliberations, the California Department of Fish and Wildlife (CDFW) Nordic switched up one of the environmental remediation measures required of the project to comply with requirements from the California Department of Fish and Wildlife (CDFW).

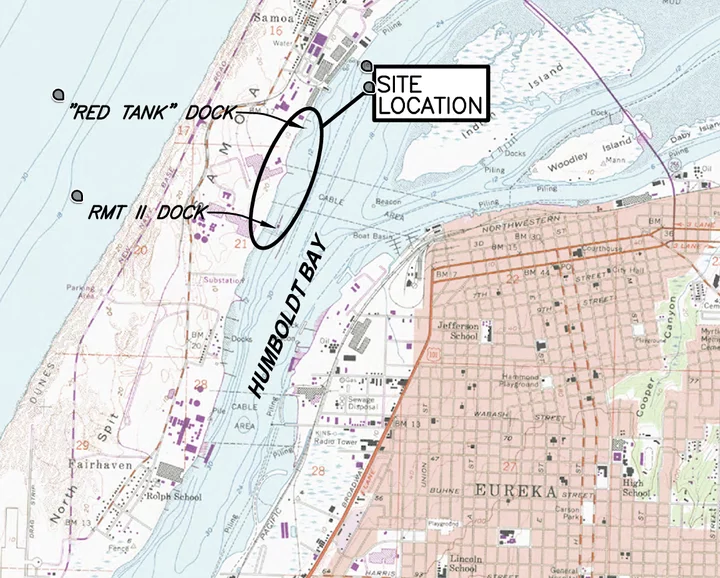

This aspect of the project involves the Humboldt Bay Harbor, Recreation and Conservation District, which previously agreed to remove nearly 1,000 derelict, creosote-treated piles and crossbeams from an old dock in Fields Landing to mitigate the impacts of baywater intake infrastructure.

The district’s underwater sea chests, which were installed decades ago for use by the pulp mill, are expected to impact Humboldt Bay’s marine life by sucking in tiny fish eggs, larvae and other planktonic organisms. They’re also expected to harm longfin smelt, a species of fish designated as threatened under the California Endangered Species Act. In December, the Army Corps of Engineers approved Section 404 Water Quality Certification permit for the seawater intake infrastructure.

However, CDFW determined that the plan to remove old pilings from the bay was insufficient to mitigate the impacts to longfin smelt. So instead, as a condition of the agency’s recently issued incidental take permit, the Harbor District must construct nearly an acre of wetland habitat, and the district must maintain and manage that habitat throughout Phase 1 of the project.

###

“Now we need to design and permit the mitigation project itself,” Thompson said. “So that will need its own permitting. We need to do CEQA [California Environmental Quality Act] again; we need a Coastal Commission permit; we need Army Corps permits. So that is a whole ‘nother project. The pile-pulling probably wouldn’t have needed quite so much.”

Nordic has identified one potential property for this wetland-building endeavor, along Freshwater Slough, though Thompson said, “Eventually, we’ll likely be building wetlands in several locations.”

The sites will be constructed in areas with freshwater influence to allow for more spawning and rearing habitat for the longfin smelt, he explained.

Chandler said this project will also help to satisfy requirements from the California Coastal Commission, though that agency has asked for additional underwater mitigation work to be done between the Harbor District’s two intake locations — one at Redwood Marine Terminal II and the other at the “Red Tank” dock in Samoa.

Map of the Harbor District’s “sea chest” baywater intake infrastructure. | Detail of image from County of Humboldt.

###

“There are several conditions to meet for that [part of the project] as well … ,” Chandler said. “So we expect to be doing that work in conjunction with the Harbor District over the next couple of years.”

As recently as last fall, Chandler was expecting that the pulp mill’s smokestack and boiler building could be demolished and removed before the end of 2025, but that’s no longer the case.

Thompson said that, as far as he knows, this is the first incidental take permit ever granted for longfin smelt in Humboldt Bay, so CDFW took extra time working with Nordic to develop a mitigation formula informed by a yearlong sampling event — or “entrainment study” — in Humboldt Bay.

Even with these new mitigation measures, local environmental groups remain wary. Jennifer Kalt, executive director of Humboldt Waterkeeper, said her organization is still concerned that the nutrient discharge from the ocean outfall pipe could increase the risk of toxic algae blooms, especially during marine heat waves like the one from 2014-16, nicknamed “The Blob.”

Kalt said she’s grateful for the Marine Monitoring Survey Plan.

“All we have to go on now is modeling, so the monitoring is really important to understand what is really happening in the ocean once the project is up and running,” she said.

As for the financial aspects of the endeavor, Chandler said pulling the plug in Maine didn’t necessarily impact the finances for the local project, which is being managed separately. But if the Trump administration implements widespread tariffs, or if the U.S. economy falters in the next couple of years, Nordic will likely have to review its list of vendors.

“Invariably there’s going to be an impact somewhere along the supply chain, both for our capital expenditures and our … operating expenses,” Chandler said.

The company’s existing investor group is largely based in Scandinavia, but Chandler said that sometime in the next few weeks, Nordic will “open the door” to U.S. investors.

Thompson argued that the recent political and economic turmoil serves to highlight the importance and value of domestic food production. And while the finish line keeps moving farther away, Chandler noted that, after six years of work, Nordic has a huge head start on any other company that might want to pursue such a project. She remains optimistic.

“What we have here is an amazing opportunity,” she said. Unlike in Maine, where the fish factory was slated to be built on forested land near a drinking water reservoir and a river that supports one of the last wild Atlantic salmon runs in the U.S. — and where a new discharge pipe would empty into an estuary with eelgrass — the local project site is a partially cleaned up brownfield property with built-in infrastructure and access to copious fresh water.

“When I talk to people, I call it a unicorn,” Chandler said, referring to the site’s project-specific amenities. “It’s just very unique.”

While the start of construction is likely years away, Thompson and Chandler said that they hope that the initial 0.93-acre wetland construction project will be sufficient to permit 2.66 million gallons per day of seawater intake from Humboldt Bay, which would be sufficient to produce up to 3,000 metric tons of fish per year in Phase 1.

The footprint of Building One, a grow-out module originally planned at over 265,000 square feet, has been reduced by 75,000 feet. The company’s existing permits allow for up to 15,000 metric tons, but Chandler said she won’t even hazard a guess on when that much production will be possible.

“I’m not going to be 100 percent confident until we’re literally breaking ground,” she said. And she expressed gratitude for the community in helping to get the project this far.

Attempts to reach the relevant personnel with both the Harbor District and CDFW before this story was published were unsuccessful.

###

PREVIOUSLY

- Coastal Commission Approves Humboldt Bay Seawater Intake System Upgrades Needed for Nordic Aquafarms Project

- Nordic Aquafarms Celebrates Coastal Commission Denial of Five Appeals to Samoa Fish Farm

- Coastal Commission OKs Wastewater Discharge Permit for Nordic Aquafarms’ Onshore Fish Farm

- Water Quality Board Awards Wastewater Discharge Permit for Nordic Aquafarms’ Planned Peninsula Facility

- Salmon OUT, Yellowtail IN: Nordic Aquafarms Announces Species Switch-Up at its Planned Humboldt Facility

CLICK TO MANAGE